How To Prevent Corrosion: Snow Plowing Equipment

Posted Feb 01, 2021 by Dave Scaturro

Your snow removal vehicles are the most important assets to your snow removal business. Without it, you wouldn’t have the bandwidth to balance your clients’ needs. Your trucks are at the front of whatever comes between you and efficient snow and ice removal. It’s important for your snow removal business to prevent vehicle rust as best you can.

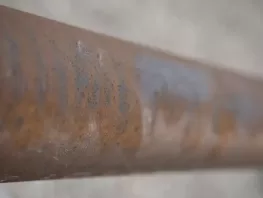

Rusting is type of corrosion that's caused by a chemical reaction that occurs when air and moisture are exposed to metal. This is common in fleet vehicles since they’re made of metal. The sheer physicality and demand of working during a blizzard is hard and so is maintaining your fleet vehicles while shielding them from the snow, ice, and corrosive rock salt.

Snow Removal Fleet Exterior Painting

Sure the layers of paint on your vehicles and equipment serve to make them look nice; however, did you know that these coatings serve to protect them as well? Unfortunately, just one coat for the entire existence of your vehicles and equipment will not provide them the extended life-span they're capable of. Soluble salts find their way through paint, causing blistering, bubbling and eventually rust and corrosion. Protective layers should be reapplied in the off season so there is no downtime when the winter storms strike.

Before re-applying a new layer of paint, all existing coatings, including paint, rust, grease, oil and dirt, should be sandblasted from the surface. Sandblasting is a common term used for blasting very fine bits of aggregate at a high-velocity to clean a surface (typically steel, metal or concrete). At Alpine our in-house sandblasting shop performs hundreds of these types of coatings throughout the year. This step is important because it removes all the existing coating and corrosion, down to the bare substrate, and creates a fresh canvas for a new coating to adhere to. Better adhesion will cause the new coating to last longer and ultimately look cleaner.

The next step is priming your vehicles and equipment. Primer is used to seal, bond, and create a stable surface for your topcoat to be applied to. We typically coat vehicles and equipment with an epoxy or zinc primer. Without a rust inhibitive primer, especially with metals, the coating will not perform correctly and may even peel off the surface.

Lastly, it is time for that protective top coat. We recommend a high performance urethane finish. Urethanes have excellent chemical resistance and hold their color and finish very well. It is important to select the right coating for your piece of equipment. Here at Alpine we will work with you to make sure we are using the paint best suited for your vehicles and equipment. Whether you are looking for a high-gloss finish, excellent durability, stand-out colors, or all of the above, Alpine will find the right solution. Our team will make sure your new coating is resilient and stands out in the field.