How to Protect Your Winter Fleet Vehicles from Corrosion

Posted Jan 04, 2021 by Dave Scaturro

Winter is officially here, and for fleet owners, harsh weather conditions can lead to headaches and high costs. Fleet vehicles are often on the road for more than 10 hours a day and during the colder months may undergo damage from abrasive and corrosive elements. Managers can protect their vehicles from freezing temperatures, corrosion and repair expenses with preventive maintenance starting now.

What Causes Corrosion?

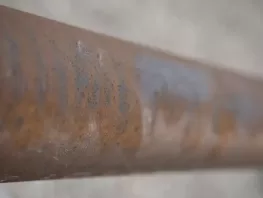

On roads across the United States, towns and cities apply sand and rough chemicals to keep drivers safe from rain and snow. But deicing agents such as magnesium chloride and calcium chloride pull moisture from the air and eat away at any metal surface causing more rust and corrosion. Blistering paint, cracking, lifting, and surface roughening or peeling are all corrosion indicators.

3 Ways to Protect Your Vehicle(s) this Winter

1. Remove Corrosive Salt Deposits with Regular Washing

Washing your vehicle after each salting event might be the most effective way to prevent corrosion. Tackle both the vehicle body and under-carriage to remove dirt and contaminants using warm water and detergent. Be sure to dry the areas properly. The longer you wait to physically remove the chloride chemicals, the more damage your commercial vehicle will endure. Some experts recommend non-toxic and biodegradable rinse-water additives that neutralize and move deicing salts.

2. Apply Anti-Corrosion Coating

Quality paints and protective coatings can help shield your vehicle from corrosion. Primers also act as cost-effective barriers between substrate metals and electrolytes, providing resistance against rock chipping. Grease, paint, epoxy coatings, zinc, and ceramic are all great anti-corrosion coatings to use to prevent corrosive damage.

Before coating, it’s important to note that individual buses, fleet vehicles and commercial trucks have differing requirements. Be sure to speak with a representative about your vehicle’s specific needs.

3. Perform Regular Maintenance and Electrical Inspections

Inspections help to identify rust and corrosion early. Not only is it easier to repair smaller corroded areas before they get out of hand — and potentially dangerous — it’s also more cost-effective. Areas to inspect: Bottom half of the vehicle, wheel-end components, brake shoe and lining, rubber materials, battery and battery cables, and wiring.

Electrical wires are also vulnerable to corrosion. The risk is especially high in the winter because of the extra moisture and exposure to salt chemicals. Fleet managers can consider vapor corrosion inhibitors — substances that slowly release a corrosion preventative compound into sealed air space. VCIs effectively protect exposed metal surfaces making it ideal for electronics under the dashboard. The protective layer shouldn’t interfere with electrical performance.

And when it comes time to update the vehicle and its wheels, consider implementing materials that are naturally resistant to corrosion such as galvanized steel, aluminum, or fiberglass. Our team can then provide our excellent shop painting services to rejuvenate your fleet vehicles. With 35 years of experience to back us up, you know that Alpine is a name you can trust when it comes to all your fleet vehicles needs.