Advanced Surface Preparation Techniques for Challenging Industrial Environments

Posted Jun 17, 2024 by Dave Scaturro

In industrial settings, the longevity and performance of coatings, flooring, and other surface treatments rely heavily on the quality of surface preparation. Challenging environments, such as those found in manufacturing plants, chemical facilities, and refineries, demand advanced techniques to ensure that surfaces are properly prepared to withstand harsh conditions. This blog explores the critical role of surface preparation and highlights advanced techniques used to achieve optimal results in demanding industrial environments.

The Importance of Surface Preparation

Surface preparation is the foundation of any successful coating or flooring application. It involves cleaning, repairing, and profiling the substrate to ensure maximum adhesion and durability of the applied materials. In challenging industrial environments, proper surface preparation is crucial for several reasons:

Adhesion: Ensuring that coatings or flooring materials bond effectively to the substrate, preventing premature failure.

Durability: Enhancing the longevity and performance of the applied materials, even under harsh conditions.

Safety: Reducing the risk of hazards such as slipping, chemical exposure, or structural failure.

Compliance: Meeting industry standards and regulations to ensure operational safety and efficiency.

Advanced Surface Preparation Techniques

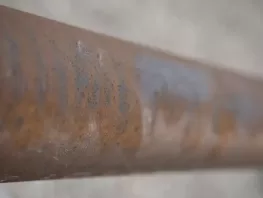

Abrasive Blasting

Abrasive blasting, also known as sandblasting, is a highly effective technique for removing contaminants, rust, and old coatings from surfaces. In challenging environments, abrasive blasting is essential for achieving a clean, profiled surface that promotes adhesion. Depending on the substrate and the specific requirements, different types of abrasive media can be used, such as sand, steel grit, or glass beads. This technique is ideal for preparing large surface areas and heavy-duty industrial equipment.

Ultra-High-Pressure Water Jetting (UHP)

UHP water jetting uses water at pressures up to 40,000 psi to remove coatings, contaminants, and even concrete from surfaces. This method is particularly useful in environments where dust and abrasive media are a concern. UHP water jetting is effective for surface preparation in chemical plants, refineries, and other sensitive areas, as it leaves no residue and minimizes environmental impact. It also provides a deep clean, ensuring that the surface is free of embedded contaminants.

Chemical Cleaning

Chemical cleaning involves using acids, alkalis, or solvents to remove grease, oils, and other contaminants from surfaces. This technique is often employed in conjunction with mechanical methods to ensure thorough preparation. Chemical cleaning is especially useful for preparing surfaces in food processing plants, pharmaceutical facilities, and other environments where hygiene is paramount. It requires careful handling and disposal of chemicals to ensure safety and compliance with environmental regulations.

Power Tool Cleaning

Power tool cleaning uses mechanical tools, such as grinders, needle scalers, and wire brushes, to remove rust, old coatings, and other surface contaminants. This method is ideal for small areas or hard-to-reach places where abrasive blasting or water jetting may not be feasible. Power tool cleaning allows for precise control and is effective for detailed work, such as preparing weld seams or intricate machinery components.

Vacuum Blasting

Vacuum blasting combines abrasive blasting with a vacuum system to contain dust and debris. This technique is particularly beneficial in environments where cleanliness and air quality are critical, such as clean rooms, laboratories, and electronics manufacturing facilities. Vacuum blasting provides the same surface preparation quality as traditional abrasive blasting while minimizing the mess and environmental impact.

Conclusion

Advanced surface preparation techniques are essential for ensuring the success of coating and flooring applications in challenging industrial environments. By employing methods such as abrasive blasting, ultra-high-pressure water jetting, chemical cleaning, power tool cleaning, and vacuum blasting, facilities can achieve the clean, profiled surfaces necessary for optimal adhesion and durability.

At Alpine Painting, we leverage these advanced techniques to provide superior surface preparation services that meet the rigorous demands of industrial settings. Contact us today to learn more about how our expertise can help protect and enhance your facility's surfaces.