The Role of Surface Preparation in High-Performance Industrial Coatings

Posted Sep 26, 2023 by Dave Scaturro

When it comes to industrial coatings, the foundation of success lies in meticulous surface preparation. While this principle holds true for any painting project, it takes on paramount importance when dealing with concrete floors. Following we discuss the significance of proper surface preparation for achieving impeccable results with high-performance coatings, shedding light on the specific challenges posed by concrete surfaces and how to overcome them.

Concrete Floors: Challenges and Solutions

Concrete floors, often poured and finished for a smooth, dense surface, present unique challenges for coating applications. The post-troweling process may involve the use of curing compounds to enhance strength and chemical properties. However, these compounds can become barriers to successful coatings due to their inadequate adhesion and film strength.

To address this, a thorough cleansing of the surface using suitable detergents or emulsion cleaning solutions should be followed by a comprehensive rinse. Testing residual compounds using muriatic acid can help identify any remnants that require additional cleaning.

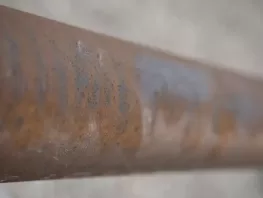

Creating an Ideal Anchor Pattern

The smoothness achieved through the troweling process can become an obstacle to coating adherence. An ideal concrete surface for coatings boasts a texture akin to 100-grit sandpaper. Achieving this requires the creation of an anchor pattern that coatings can grip onto effectively.

Acid etching and abrasive blasting are two effective methods to attain this texture. In the case of acid etching, a meticulous process involving muriatic acid solution is employed. This process mandates thorough precautions and safety measures, ensuring the acid is handled with care, and adhering to material safety data sheets (MSDS) guidelines.

Environmental Considerations: A Critical Factor

As with any coating application, environmental conditions play a pivotal role in ensuring the success and longevity of the coatings. In the realm of concrete surfaces, factors like surface temperature and humidity levels need special attention, particularly during cold or humid weather. Calculating the dew point becomes imperative, ensuring an environment conducive to proper drying and adherence.

Striving for Excellence

Alpine Painting and Sandblasting understands that the journey to exceptional coatings begins with rigorous surface preparation. By addressing the challenges posed by concrete surfaces head-on and employing meticulous techniques like acid etching, the foundation for coating success is laid. With a commitment to safety, quality, and expertise, Alpine stands as a partner ready to elevate your industrial coatings to new heights of performance and durability.

For a coating that endures, let the expertise of Alpine Painting and Sandblasting guide your way.