5 Benefits of Hiring a Professional Sandblasting Company for Your Commercial Project

Posted Jun 26, 2023 by Dave Scaturro

Sandblasting is a method that uses high-pressure materials to clean surfaces. Before applying or reapplying paint to any type of equipment, existing paint coatings and debris like rust, grease, oil, and dirt need to be removed. This ensures the surface area is clean and smooth allowing new coatings to adhere properly, last longer, and look nicer. Sandblasting uses fine bits of aggregate at a high velocity and is an incredibly effective way to clean a surface (generally steel, metal, or concrete). Hiring a professional sandblasting company for your commercial project is an excellent idea as they have the expertise to select the right materials for the job.

Here are some benefits of sandblasting that make it a great choice for your commercial project:

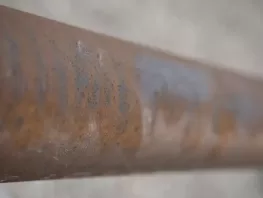

1. Restores Rusty Equipment

Rust is one of the biggest challenges faced by commercial and industrial businesses. Rust oxidizes metal and causes damage to equipment, which can affect your operation. Sandblasting is an efficient way to remove rust and make the equipment look new. This is especially useful if you have food industry equipment that has accumulated rust and needs to be brought back to its original look.

2. Smooths Surfaces for Painting

Sandblasting is an effective method of smoothing surfaces before painting, ensuring that the paint goes on evenly without any rough spots. This is especially useful when painting surfaces that have accumulated several coats of paint over the years. Sandblasting is versatile and can prep a wide variety of surfaces, making them ready for painting. For example, it is an excellent way to prepare a piece of machinery for a fresh coat of paint in a restoration project.

3. Blasts Oil and Contaminants

Businesses that have equipment that accumulates oil and other contaminants will eventually require a thorough cleaning. Manual cleaning is effective, but it cannot remove stuck-on oil and grime that has accumulated over a long period of time. Sandblasting removes these contaminants and ensures that precision parts are clean and free of dirt and debris. It doesn't require harsh chemicals, making it a safe and environmentally friendly option.

4. Non-Toxic and Safe

Sandblasting is a power washing technique that utilizes materials that are non-toxic and safe for your equipment and the environment. Industrial quality equipment is strong and can handle sandblasting without any damage. Unlike other cleaning processes, there is no need for harsh chemicals, which reduces the risk of equipment damage or any harm to the environment.

5. Saves Time

Sandblasting saves time, making it an ideal solution for commercial and industrial businesses that need to keep downtime to a minimum. The high-pressure material quickly blasts away pollutants from surfaces, making cleaning jobs quick and efficient. A job that would take hours to clean manually can be completed in a matter of minutes through sandblasting.

Hiring a professional sandblasting company, such as Alpine Painting and Sandblasting, for your commercial project offers several benefits. It restores rusty equipment, smooths surfaces for painting, blasts oil, and contaminants, is non-toxic and safe, and saves time. With its versatility and efficiency, sandblasting is an excellent choice for any commercial or industrial business that requires surface cleaning or preparation.

Our experienced team has more than 45 years of experience in sandblasting and would be happy to discuss the best options for your next commercial or industrial project. Give us a call today to get started!