3 Ways to Prevent Corrosion to Your Winter Equipment

Posted Nov 21, 2022 by Dave Scaturro

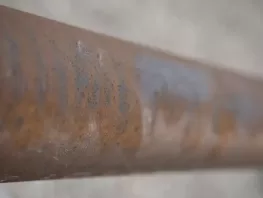

Dirt, salt, acid and moisture are just a few aspects of winter that vehicles and equipment have to contend with. Without the proper coatings (and coating process), that equipment may be subject to corrosion, rust and ultimately may not work properly or last as long as it should.

We recommend preventative maintenance to winter equipment to ensure it’s prepared for the harsh conditions the season can bring. This includes everything from surface preparation to painting. Here are 4 steps our expert team takes to ensure our clients’ winter equipment is prepared and ready for all conditions:

Sandblast

Before applying or reapplying paint to any type of equipment, existing paint coatings and debris like rust, grease, oil and dirt need to be removed. This ensures the surface area is clean and smooth allowing new coatings to adhere properly, last longer and look nicer. Sandblasting uses fine bits of aggregate at a high velocity and is an incredibly effective way to clean a surface (generally steel, metal or concrete). Our team at Alpine can provide sandblasting services onsite or in-house in our sandblasting shop.

Prime

Priming is an important next step in any winter equipment project. Primer helps to seal, bond and create a stable surface for the topcoat to be applied to. Our team typically coats vehicles with a rust inhibitive primer, like epoxy or zinc, to ensure it performs correctly.

Paint

The final step is a protective topcoat. This serves as the first line of protection for any vehicle or equipment and keeps it looking top notch. We recommend using a high performance urethane finish, which offers chemical resistance and holds its finish well.

Our experienced team can provide topcoat recommendations for your vehicles and equipment, whether you’re seeking a high-gloss finish, vibrant colors, durability or all of the above. We can also customize your equipment with logos, including matching the color, font and design.

Let our team help you ensure your vehicles and equipment are winter-ready. Give us a call today to start your estimate and check out our portfolio of past projects here.