Construction Equipment Restoration

Posted Jan 13, 2020 by Dave Scaturro

Construction owners - this one is for you.

As a construction company, your equipment builds your brand, and appearance is a large part of what customers see. Your image includes everything tangible with your service and more. Just like military vessels, your construction equipment needs to be clean, uniform, and represent your brand through visible colors and proper logo placement. This way your service can have that professional look while providing a top-quality job. Don’t let your abused vehicles, trailers, and heavy construction equipment tell your customers to go elsewhere.

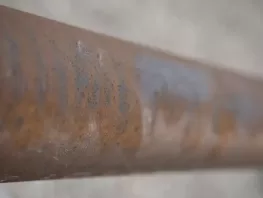

Take the time during the winter months to restore your equipment. It’s expected that with continual use heavy construction equipment will wear down especially during peak seasons. Over time, dirt and rust may begin to stain your metal surfaces, so that it no longer has that the original luster from when it was first purchased. Even though it still can perform quality work, customers perceive it to be less efficient or it takes away from your company brand.

Send it to Alpine!

Our facility has a fully enclosed blast barn and two large industrial spray booths. Our policy at the shop is to paint whatever can fit through our door. This includes large dump trucks, front loaders, drill rigs, compressors, tanks, structural steel, pressure vessels, heat exchangers and more.

You can either bring over your equipment and we can price it up for you on the spot or feel free to send us pictures, dimensions, quantities and as much info as possible so we can accurately provide you with a detailed proposal. Our shop project manager has years of experience and can examine your equipment to help determine the condition of its surface and recommend the right solution for you.

Shop Services

Include: sandblasting and applying high performance industrial coatings. We have a variety of sandblasting abrasives, which can remove years of rust and old paint from your machinery. Our unique abrasives will all provide a different surface profile on your steel. When corrosion occurs on the surface of your equipment, the rust can actually deteriorate the steel. Sandblasting will remove the paint and existing rust down to the bare steel. Once that prep work is finished, our team can start applying the coatings.

The type of paint that is most commonly used for construction machines is a high build epoxy/urethane paint system. These coatings adhere well to steel surfaces and are designed to be durable in industrial exposures. They are intended to be exposed to outdoor weather conditions such as sunlight and rain. The high solids content ensures adequate protection of sharp edges, corners and welds.

Speaking of welds, we have an in-house welder to help ensure paint isn’t the only thing holding your machine together. Our professional welders will help inspect your equipment and bring any concerns to your attention prior to being painted.

Want to use your company colors, our pleasure. You can choose from any color in the rainbow. Give us a color number and we can match it exactly. This way, your heavy machinery can help define your company image. Let the professionals here at Alpine Painting give you a painting price today to make your machines look new again.