High Performance Industrial Coating Systems - Plural Component Material

Posted Sep 13, 2013 by David Guy

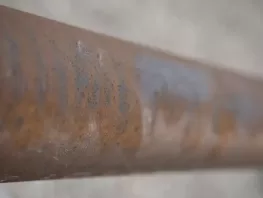

Painting projects in harsh environments, (Such as Potable Water or Waste Water Tanks), applied with average coating solutions will surely fail. For these involved projects, a facility manager or engineer should consider specifying a plural component coating system. This type of coating has a number of benefits that make these paint systems high performance products, the go-to compounds for jobs that require heavier duty material being applied as they are far from your average paint or coating material.

Plural component coatings are known as high performance materials for a reason, and possess properties which make them ideal for situations where normal paint will most likely fail. These reliable materials are chemical resistant, shock resistant, flexible, and can be used for a number of purposes including tank lining, roof coatings, secondary containment systems and waterproofing. How different are these plural components materials from average paints or coatings? Specialty Products, Inc., a Washington company produced a spray on coating so strong and durable that it is used in war zones to help effectively mitigate the damage from fragmentations from explosions.

What makes these coatings so different from their non-high performance counterparts comes down to the chemistry. Polyurea elastomeric paint and coating systems have been around for two decades, but are constantly improving, moving further and further away from average paint solutions. These coatings are created by reactions from isocyanate components combined with specially formulated resin blends, and it is this resin blend that will determine if the coating falls under the label of polyurethane, polyurea or a hybrid of the two.

The prime markets for plural component systems are waste water treatment facilities, chemical or manufacturing facilities and the like. Plural components can be applied to anything from concrete secondary containment linings to steel tanks for water treatment. Plural component spray foam is used frequently in the roofing business. Spray foam insulation can actually provide additional strength to the structure that it is being applied to.

Because these types of coatings are so technically advanced, it is important that they are applied the correct way to ensure they are utilized to their full potential. As such, it is recommended that any structure owner planning on using this durable material to protect their infrastructure from chemicals, environmental hazards or the like contact an experienced contractor who can apply the coatings or paint effectively and safely. The coatings themselves are indeed dependable, so long as they are applied correctly. Readers located around NJ, NY, CT or PA can contact a local contractor such as Alpine Painting for more information on the benefits of the service, online or at 866-596-0349.

By Dave Scaturro, Sales Director for Alpine Painting.

Credit to: Buck, Kevin A. . "Formulating Polyureas." Paint Square. Mar 2013: Web.

Gardner , Michelle. "Having a Blast With Polyurea Coatings." CoatingsPro. Nov 2012: Print. 13 Sep. 2013.