The Importance of Hiring a Certified Painting Contractor for Your Tank Painting Project

Posted Jan 31, 2022 by Dave Scaturro

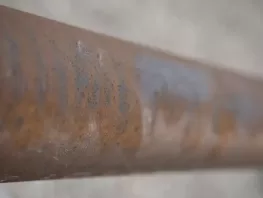

As a responsible business owner, you take all business operations seriously and address problems before they escalate. If you are the owner of a single large water tank or tower, an entire tank farm, or a wastewater treatment facility, prioritizing the integrity of your tank(s) should be no different. If you wait for the first signs of corrosion to appear on your storage tank before taking any action, you are putting at risk the tank itself and its valuable content.

Negligence can also create additional problems down the road. For example, if rust appears beneath a tank’s protective coating, you will likely need a full-scale abrasive blasting to remove it. As part of a sound maintenance plan, you should schedule a tank painting before any problems take hold, and you should do so with a contractor that has experience painting tanks.

Understanding the Nuances of Individual Tank Features

An experienced contractor will be familiar with tanks of all shapes and sizes, and understand how their specific functions will inform how they are maintained. There is quite a bit of range in variety out there, including elevated and ground storage tanks, standpipe tanks and bullet tanks, as well as, clarifier tanks and digester tanks. Knowing how each differs will determine the plan of action for tackling the painting job. But just as important, a qualified painting contractor will prioritize fall protection, confined space considerations, ventilation and coating selection regardless of the nature of the tank to be serviced.

Below are considerations an experienced contractor will take when approaching various types of tanks:

Elevated Water Tanks

Fall protection is critical when coating the exteriors of elevated tanks. When crews are moving around the exterior of a tank hundreds of feet above the ground, it is especially important to make sure the hired contractor has the proper safety credentials and certifications. Alpine takes great pride in its safety record.

Elevated tanks often display logos that act as an identifier and point of pride for a municipality or other utility. When executing an external painting of an elevated tank, it is important that the hired contractor also has experience painting structures with high-visibility graphics work.

Tank Farms

Tank farms share some of the same considerations as other types of tanks, but they do have their own unique challenges. For one, a tank farm can be significant in size so a large crew may be necessary. An experienced contractor will need to have the manpower available to handle such a sizable painting job and to make sure it gets done on schedule.

When reviewing a prospective contractor’s proposal, the person doing the hiring should never doubt that the size of the crew will become extremely important very quickly. If an average size tank requires a crew of at least four – two to paint the inside, while another is operates a blast pot or other machinery, and the other is on alert for any sign of trouble within the confined space. Once you multiply the number of crew members per tank by the number of tanks on the farm, you are looking at quite a lengthy project if your contractor’s crew consists of just a few people.

Additionally, as all the tanks on a tank farm are connected to each other, linked by miles of pipeline and high-efficiency pumps and hydrants required to protect against corrosion, a seemingly simple tank-painting job will evolve into an extensive scope of work that necessitates a contractor with the proper experience.

Clarifiers

Clarifier tanks at wastewater treatment plants can be harsh environments, with chemicals to treat the water being especially damaging on the tank’s coatings. Additionally, the settling, raking, pumping, sludging, clarifying and filtration processes can be very deteriorating to the tanks coatings, so it’s essential to get the right coating applied correctly the first time around, or it simply will not last.

Alpine is Your Expert Tank and Vessel Painting Contractor

Alpine Painting has a history of excellence when it comes to its tanks painting services. In addition to our excellent field service, we also offer shop services for smaller tank and vessel projects. The same skill and care that is applied to our larger projects in the field is mirrored in our shop services.

No matter what the intended use, our team of skilled craftsmen will work with you to make sure you receive a finished product that serves all of your needs. Give Alpine Painting a call today at (973) 279-3200 to get a free estimate.