How to Schedule Painting for an Active Industrial Facility Without Shutting Down Production

Posted Aug 25, 2025 by Dave Scaturro

Let’s be real—shutting down production just to slap some paint on a wall? That’s a non-starter for most industrial facilities. Every hour you’re down is money out the door, and in New Jersey’s competitive manufacturing, warehousing, and logistics world, nobody has time for that.

But here’s the thing—letting those walls, ceilings, tanks, or floors go too long without maintenance is just asking for bigger problems. Corrosion doesn’t care about your schedule. OSHA sure doesn’t care either. So, how do you get the job done without grinding everything to a halt? That’s where a little strategy—and the right contractor—makes all the difference.

Step One: Map Out Your “No-Go” Zones

Before the first drop cloth gets laid down, you need to identify the areas that simply cannot go offline during business hours. We’re talking production lines, high-traffic forklift paths, or temperature-controlled storage zones.

At Alpine Painting, we work with your facility manager to color-code the building—literally on a floor plan—so everyone knows what’s fair game and what’s strictly hands-off during peak times.

Step Two: Staggered Scheduling & Off-Hours Work

We’ve painted everything from pharmaceutical plants in Somerset to warehouse giants in Elizabeth without a single production hiccup. How? By splitting projects into phases and running crews on off-hours—overnights, weekends, and even holiday breaks if needed.

It’s like doing surgery while the patient’s still walking around. You get one area done, clean it up, and the facility rolls on like nothing happened.

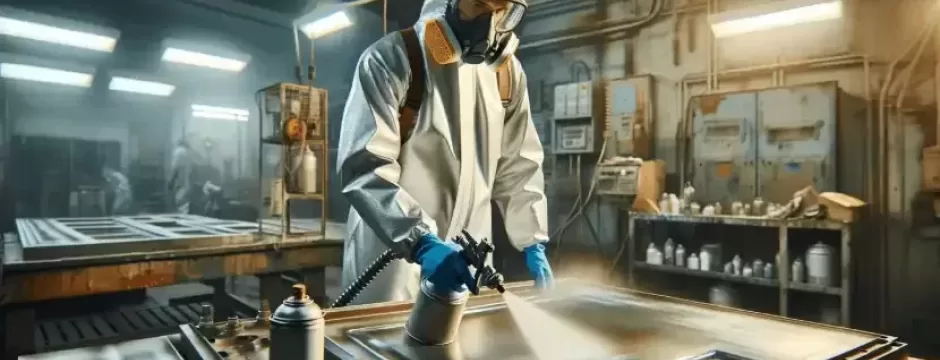

Step Three: Dust, Noise & Safety Control

Industrial painting isn’t just about brushes and rollers—it’s sandblasting, spraying, grinding. All that comes with noise, dust, and fumes you don’t want near sensitive equipment or products.

We set up containment zones—think giant shrink-wrap enclosures with negative air systems—to keep debris locked in. That way, your QA team sleeps easy knowing no dust is drifting into production.

Step Four: Choosing the Right Coatings for Speed & Durability

Here’s where our decades in industrial painting pay off. We use fast-curing, high-performance coatings—like quick-dry epoxies and polyurethanes—that let you get back to business in hours, not days. And because this is industrial work, we’re not just going for pretty. These coatings resist chemicals, abrasion, and heavy traffic so you’re not redoing the job next year.

Step Five: Communication is King

This might be the most important piece of the puzzle. We keep a daily log of what’s getting done, which zones are in play, and what’s next—so your facility team isn’t left guessing. When everybody’s in the loop, there are no surprises.

Bottom Line

You don’t have to choose between keeping the lights on and keeping your facility in top shape. With the right planning and an experienced contractor who understands how to work around your operations, you can have both.

And if you’re in New Jersey and need industrial painting, floor coating, or sandblasting without the downtime headaches, Alpine Painting is your crew. We’ve been doing this since before “supply chain” was a buzzword, and we know how to keep your business moving while we work.

Ready to tackle that painting project without losing a single production shift?

Contact Alpine Painting & Sandblasting Contractors today and let’s build a plan that works on your clock—not ours.