How to Plan Your Industrial Painting Projects for the New Year in New Jersey, New York, and Pennsylvania

Posted Jan 05, 2026 by Dave Scaturro

For facility managers, plant engineers, and operations teams across New Jersey, New York, and Pennsylvania, the start of a new year is more than a calendar change. It is an opportunity to plan strategically, protect critical assets, and avoid costly disruptions later in the year.

Industrial painting projects are often treated as reactive necessities, only addressed when corrosion, coating failure, or safety concerns become impossible to ignore. Unfortunately, this approach frequently leads to emergency repairs, unplanned shutdowns, and higher costs.

Planning industrial painting projects early in the year allows facilities throughout the Tri-State region to stay ahead of deterioration, align work with operational schedules, and extend the lifespan of infrastructure that supports daily operations.

Why January Is the Best Time to Plan Industrial Painting Projects

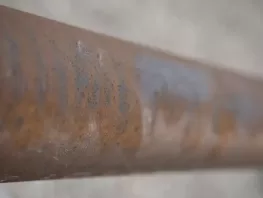

January offers a unique advantage for industrial facilities in the Northeast. Winter conditions across NJ, NY, and PA expose weaknesses in coatings that might remain hidden during warmer months. Freeze-thaw cycles, snow, salt exposure, and condensation all accelerate coating breakdown and make early-stage failures easier to detect.

Facilities that conduct assessments and planning in January gain a full picture of their needs before spring and summer schedules fill up. This proactive approach allows decision-makers to evaluate priorities calmly rather than reacting under pressure later in the year.

Early planning also provides greater flexibility. Contractors have more availability, material lead times are easier to manage, and projects can be scheduled to minimize operational impact.

Start with a Comprehensive Facility Assessment

Every successful industrial painting plan begins with a detailed assessment. Facilities across New Jersey, New York, and Pennsylvania face different environmental challenges depending on location and use. Coastal facilities in New Jersey may deal with salt exposure, while urban facilities in New York experience pollution and traffic-related wear. Pennsylvania plants often contend with older infrastructure and heavy seasonal moisture.

A professional facility assessment should evaluate:

Structural steel and support systems

Tanks, silos, and secondary containment areas

Floors, especially in high-traffic or chemical-exposed zones

Ceilings, trusses, and overhead piping

Exterior façades and building envelopes

January assessments often reveal cracking, peeling, rust bleed-through, moisture intrusion, and coating delamination that may not be visible during warmer months. Identifying these issues early allows facilities to plan targeted repairs rather than full-scale recoats.

Prioritize Critical Areas to Maximize Budget Efficiency

Not all areas of a facility require immediate attention. One of the most important benefits of early planning is the ability to prioritize work based on risk, safety, and long-term impact.

High-priority areas often include:

Corrosion-prone steel

Safety-critical walkways and floors

Tanks and containment systems

Areas exposed to chemicals, moisture, or extreme temperatures

By addressing these zones first, facilities can prevent structural deterioration and safety hazards while spreading costs over the year. This approach is especially valuable for large industrial sites common throughout NJ, NY, and PA.

Align Painting Projects with Operational Downtime

Industrial facilities rarely shut down completely, but most experience planned maintenance windows, seasonal slowdowns, or reduced production periods. Planning painting projects early allows work to be aligned with these windows rather than disrupting operations unexpectedly.

Facilities that coordinate painting with scheduled shutdowns benefit from:

Reduced downtime

Improved safety conditions

Faster project completion

Lower overall project costs

In the Northeast, winter shutdowns are common in manufacturing, food processing, pharmaceutical, and utility facilities. January planning ensures painting and coating work can be completed efficiently during these periods.

Choose Coating Systems Designed for Northeast Conditions

The climate across New Jersey, New York, and Pennsylvania is demanding. Temperature fluctuations, humidity, snow, salt, and industrial pollutants all place stress on coatings. Selecting the right coating system is critical to long-term performance.

High-performance industrial coatings such as epoxies, urethanes, zinc-rich primers, and moisture-cure systems are often better suited for Northeast environments. While these systems may have a higher upfront cost, they typically deliver longer service life and reduced maintenance frequency.

Planning in January allows facility managers time to evaluate coating options carefully rather than making rushed decisions later in the year.

Build a Predictable Project Timeline

One of the biggest advantages of early planning is schedule control. Spring and summer are peak seasons for industrial and commercial painting across NJ, NY, and PA. Facilities that wait until warmer months often face limited contractor availability and compressed timelines.

January planning allows facilities to:

Secure preferred scheduling

Lock in manpower availability

Coordinate materials and access requirements

Avoid peak-season pricing pressure

Predictable scheduling reduces stress for operations teams and improves overall project outcomes.

Integrate Painting into a Long-Term Maintenance Strategy

Industrial painting should not be treated as a one-time event. Facilities that perform best over time view painting as part of an ongoing maintenance strategy.

Long-term planning includes:

Annual inspections

Scheduled touch-ups

Corrosion monitoring

Multi-year recoating cycles

This approach extends coating life, reduces emergency repairs, and improves budgeting accuracy. Facilities throughout New Jersey, New York, and Pennsylvania that adopt preventive maintenance strategies consistently outperform those relying on reactive repairs.

The Cost of Waiting Too Long

Facilities that delay planning often pay a price. Emergency repairs typically cost more, disrupt operations, and limit coating options. Minor issues that could have been addressed during planned maintenance windows often escalate into structural problems that require extensive repair.

January planning helps facilities avoid these scenarios by identifying risks early and creating a clear roadmap for the year ahead.

Planning Early Is a Competitive Advantage

Industrial facilities that plan painting projects early operate more efficiently, protect assets longer, and maintain safer environments. In competitive markets across NJ, NY, and PA, this proactive approach can be the difference between smooth operations and costly disruptions.

Final Thoughts

Planning industrial painting projects in January is not about immediate execution. It is about clarity, control, and long-term performance. Facilities across New Jersey, New York, and Pennsylvania that take the time to assess, prioritize, and schedule early are better positioned for success throughout the year.

With the right plan in place, industrial painting becomes a strategic investment rather than an operational emergency.