Facility Painting Budget Planning for 2026: What Owners in NJ, NY, and PA Should Know

Posted Jan 12, 2026 by Dave Scaturro

For commercial and industrial property owners across New Jersey, New York, and Pennsylvania, facility painting is often viewed as a necessary expense rather than a strategic investment. However, when painting and coating projects are properly budgeted and planned, they play a critical role in protecting assets, maintaining safety, and controlling long-term operating costs.

As 2026 begins, now is the ideal time to take a closer look at how painting fits into your facility budget and how proactive planning can prevent costly surprises later in the year.

Why Painting Should Never Be an Afterthought

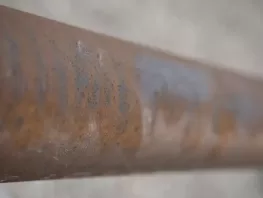

Too often, painting projects are deferred until visible deterioration appears. By the time peeling paint, corrosion, or surface failure becomes obvious, damage is usually already underway beneath the surface.

Facilities throughout NJ, NY, and PA that rely on reactive repairs often experience:

Emergency shutdowns

Premium contractor pricing

Limited coating options due to time constraints

Increased safety risks

Accelerated structural deterioration

Proactive budget planning allows owners to take control of scope, scheduling, and cost rather than reacting under pressure.

Understanding the True Cost of Delayed Painting

When coatings fail, the cost is not limited to repainting alone. Corrosion can compromise steel, moisture can damage concrete, and neglected surfaces can create safety hazards that expose owners to liability.

In older buildings common throughout New York City, Northern New Jersey, and Pennsylvania, deferred maintenance often leads to more extensive surface preparation requirements, higher labor costs, and longer project timelines.

Budgeting early helps facilities avoid paying for problems that could have been prevented.

Key Factors That Influence Painting Budgets in the Tri-State Region

Several region-specific factors affect painting costs in NJ, NY, and PA:

Climate and Weather Exposure

The Northeast experiences extreme temperature swings, high humidity, freeze-thaw cycles, and heavy precipitation. These conditions accelerate coating breakdown and require more durable systems.

Building Age and Construction Type

Many commercial and industrial buildings in the region were constructed decades ago. Older substrates often require extensive preparation before coatings can be applied properly.

Facility Use and Exposure

Manufacturing plants, warehouses, pharmaceutical facilities, and water treatment plants face chemical exposure, moisture, and abrasion that demand specialized coating systems.

Access and Safety Requirements

High ceilings, confined spaces, tanks, and active operations increase labor and safety planning costs.

Understanding these factors allows owners to budget accurately rather than relying on rough estimates.

Preventive Maintenance as a Budgeting Strategy

Preventive maintenance is one of the most effective ways to control facility painting costs over time. Rather than budgeting for large, infrequent repainting projects, facilities can spread costs more evenly through annual inspections and targeted touch-ups.

Preventive maintenance programs typically include:

Annual coating inspections

Early corrosion detection

Touch-up painting

Sealant and joint repairs

Scheduled recoating cycles

Facilities across New Jersey, New York, and Pennsylvania that adopt maintenance programs often reduce total painting spend while extending coating life.

Prioritizing Projects Without Overextending Budgets

Not every surface needs attention in the same year. Effective budget planning focuses on prioritization rather than perfection.

High-priority areas typically include:

Safety-critical zones

Corrosion-prone steel

High-traffic floors and walkways

Tanks and containment systems

Areas exposed to moisture or chemicals

Lower-risk areas can be scheduled for future years, allowing owners to manage costs without compromising safety or asset protection.

Aligning Budgets with Operational Schedules

Painting projects should be planned around facility operations, not the other way around. Early budgeting allows work to be scheduled during shutdowns, off-hours, or seasonal slowdowns.

Facilities that align budgets with operational calendars benefit from reduced downtime, improved safety, and faster project execution.

Why January Budget Planning Makes a Difference

January is an ideal time for budget planning because:

Contractors have greater availability

Project scopes can be refined without urgency

Material lead times are easier to manage

Owners can secure preferred scheduling

Facilities that wait until spring often face higher costs and limited options.

Long-Term Financial Benefits of Strategic Painting Budgets

Facilities that plan painting strategically see benefits beyond cost savings. Improved appearance enhances tenant satisfaction, safer environments reduce liability, and well-maintained assets retain value longer.

Painting is not just maintenance. It is risk management, asset protection, and brand preservation.

Final Thoughts

Facility painting budgets should reflect long-term strategy, not short-term reaction. Owners in New Jersey, New York, and Pennsylvania who plan early gain control over costs, schedules, and outcomes.

A well-planned painting budget protects facilities today and preserves value for years to come.