Cleanroom Painting Protocols for Life Sciences: Compliance and Best Practices

Posted Nov 13, 2023 by Dave Scaturro

The life sciences industry, encompassing pharmaceuticals, biotechnology, and healthcare, operates within a realm where precision and cleanliness are paramount. Cleanrooms are at the heart of this industry, ensuring the sterile and controlled environments necessary for research, development, and manufacturing. But what about cleanroom painting? How does it align with the stringent standards of the life sciences sector? In this blog, we'll explore the importance of adhering to cleanroom painting protocols, compliance, and best practices.

The Role of Cleanroom Painting

Painting a clean room isn't merely an aesthetic choice; it's an essential part of maintaining the room's cleanliness and functionality. Here's why cleanroom painting is indispensable:

Maintaining Sterility: In the life sciences industry, cleanliness is often a matter of life and death. Sterility is non-negotiable, and cleanroom painting helps maintain aseptic conditions.

Enhancing Visibility: Appropriate paint can improve lighting and visibility within cleanrooms, which is crucial for precision work in laboratories and manufacturing.

Safety and Protection: Quality paint also serves as a protective barrier for the cleanroom walls, safeguarding against wear and damage, and contributing to the longevity of the facility.

Standards and Protocols

To meet the unique requirements of cleanrooms in the life sciences sector, there are specific standards and protocols that must be followed. A few of these include:

ISO Standards: The International Organization for Standardization (ISO) sets international standards for cleanrooms. ISO 14644-1 is the primary standard, which outlines the classification of air cleanliness and contamination levels.

GMP Regulations: Good Manufacturing Practices (GMP) regulations establish quality control and risk management for cleanroom operations. Compliance with GMP is vital to ensure the safety and efficacy of products.

USP Standards: The United States Pharmacopeia (USP) provides guidelines for compounding and sterile preparations, ensuring the integrity and sterility of pharmaceutical products.

Materials Selection: Cleanroom paint must meet the stringent requirements of the FDA, especially when used in pharmaceutical manufacturing areas. It should be non-toxic and easy to clean.

Cleanroom Painting Best Practices

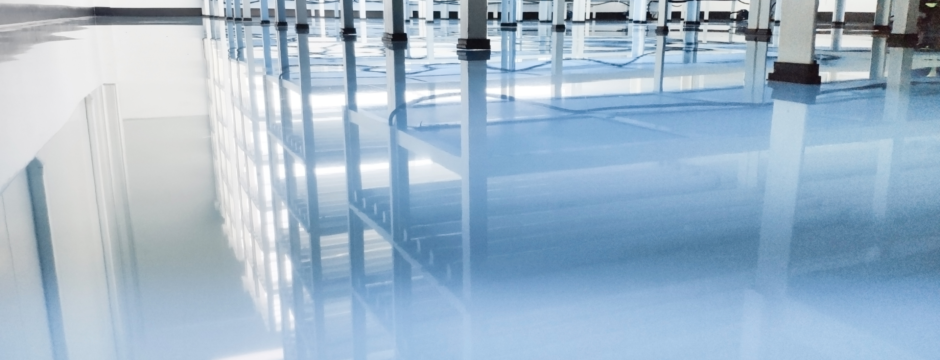

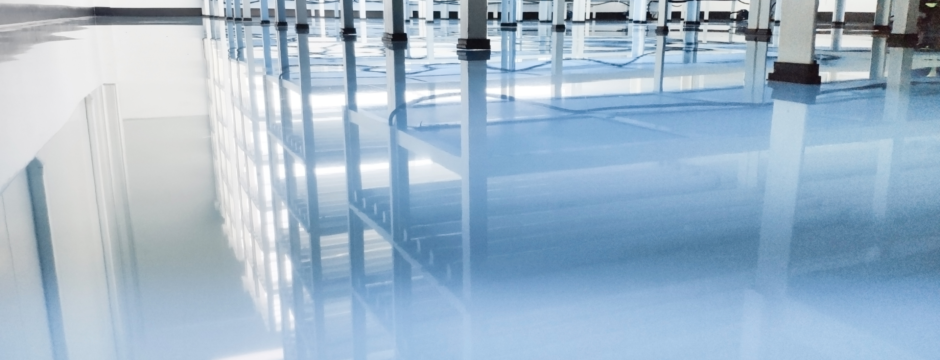

Proper Surface Preparation: The foundation of any painting project is surface preparation. In cleanrooms, this is even more critical. Surfaces should be free of contaminants, smooth, and non-porous.

Specialized Paints: Cleanroom paint should be free from volatile organic compounds (VOCs) and other contaminants. Epoxies, urethanes, and polyurethanes are often the coatings of choice due to their chemical resistance and low VOC content.

Contamination Control: All equipment used in the painting process should be meticulously cleaned and maintained to prevent any contamination.

Professional Application: Cleanroom painting is not a DIY project. It requires professional painters experienced in cleanroom protocols. Alpine Painting offers a team of experts who understand the specific requirements of life sciences cleanrooms.

Conclusion

In the life sciences industry, cleanroom painting isn't just about aesthetics; it's about maintaining the integrity of the research, development, and manufacturing processes. Cleanrooms adhere to stringent protocols and standards to ensure sterility and product quality, and the painting within these environments must align with these high standards.

For life sciences companies, it's essential to work with experienced painting contractors who understand cleanroom painting protocols, compliance, and best practices. Alpine Painting, with its extensive experience in the field, ensures that your cleanroom painting project meets the rigorous demands of the industry.